Loading & Securing Training with Mentor

Training and support / Loading and securing plant equipment training

Loading & Securing Plant Equipment Training with Mentor

Overview

HAE EHA is working in partnership with Mentor, the UK’s leading workplace transport training provider, to deliver their specialised courses covering loading and securing, counterbalance trucks and plant moving. Mentor has the UK’s largest approved instructor network and offers genuine nationwide coverage for consistent training that meets the required standards, every time.

Programme Content

Click below to expand for a full breakdown of the content of each course. Other Materials Handling Equipment courses are also available so please enquire for more information.

Plant Loading & Securing onto Trailer or Tail Lift Vehicle

Aim

To provide tool hire industry drivers, vehicle loaders and responsible managers, with the knowledge and skills to comply with current legislation and guidance. To ensure loads are loaded correctly and safely to prevent a lost load.

Course Duration

This essential course has been created to meet the specific challenges of the tool hire sector to combat the challenges of loading mixed, complex loads of different sizes, weights and materials and multi-drop deliveries. Using the principles of load security and adapting it tool hire sector, this course provides the knowledge and guidance on how plant equipment should be prepared and secured, for the safe transportation on the public highway.

The course consists of a mixture of classroom and practical demonstrations and practice and testing of delegates for confirmation of learning and is a HAE EHA approved course.

Elements Covered

Legislation and guidance, including:

Experience Levels

Suitable for all levels who have hd plant moving course or previous experience.

Practical Hands-on Training

This includes various lashing methods and how to adapt and to secure loads, use of edge protectors, winch operation and deploying, mounting and dismounting of trailer.

Facilities and Equipment Required

Beavertail Plant Loading & Securing

Aim

To provide tool hire industry drivers, vehicle loaders and responsible managers, with the knowledge and skills to comply with current legislation and guidance. To ensure loads are loaded correctly and safely to prevent a lost load.

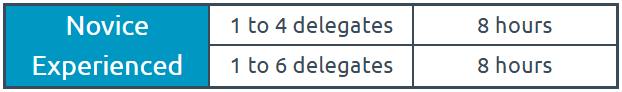

Course Duration

This essential course has been created to meet the specific challenges of the tool hire sector to combat the challenges of loading mixed, complex loads of different sizes, weights and materials and multi-drop deliveries. Using the principles of load security and adapting these to the tool hire sector, this course provides the knowledge and guidance on how plant equipment should be prepared and secured, for the safe transportation on the public highway.

The course consists of a mixture of classroom and practical demonstrations and practice and testing of delegates for confirmation of learning and is a HAE EHA approved course.

Elements Covered

Legislation and guidance, including:

Experience Levels

Suitable for all levels who have hd plant moving course or previous experience.

Practical Hands-on Training

This includes various lashing methods and how to adapt and to secure loads, use of edge protectors, winch operation and deploying, mounting and dismounting of beavertail.

Facilities and Equipment Required

CPC Training

The course is also available as Driver CPC-accredited. It counts as 7 hours towards the 35 hours of periodic training required every 5 years to retain a Certificate of Professional Competence to drive a lorry.

AITT Managing Forklift Operations

Aim

To provide managers/supervisors with the knowledge and skills to safely manage the use of forklifts in the workplace, effectively and legally. To empower them to apply best practice, resulting in significantly reduced risk of accidents and incidents, damage, disruption and the associated costs, thereby contributing directly to profitability.

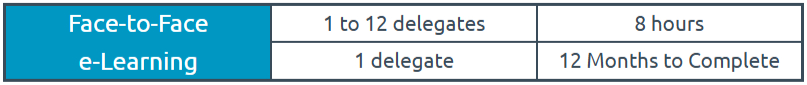

Course Duration

This course is approved by AITT as being suitable to meet the requirements of UK health and safety legislation, specifically, the Approved Code of Practice for – Rider-operated lift trucks L117 and regulation 9.2 of the Provision and Use of Work Equipment Regulations 1998 (PUWER).

Objectives

This course is available as both face-to-face training and e-learning. On successful completion of the course delegates will:

Elements Covered

Counterbalance FLT Training

Aim

To provide delegate(s) with the correct skills, knowledge and understanding to be able to safely and effectively use a counterbalance forklift truck (up to and including 5 tonne – ABA category B1).

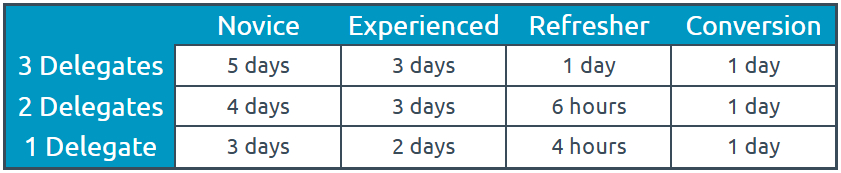

Course Duration

Objectives

To reduce the risk of accidents as a result of the unsafe use of the Counterbalance truck.

Elements Covered

Pre-Qualification Criteria

Delegates attending this course do not require any prior qualification. They should be:

Methodology

The trainer will employ a highly facilitative approach to the training with limited group delivery, incorporating directive and participative styles. The major efforts need to be practical in nature and will include support of theoretical elements to aid understanding.

Reflective practices and use of feedback techniques will be utilised to improve training and capability outcomes.

Course Test & Certification

At the conclusion of the course, delegates will undertake a short written test relating to the course content. In order to issue an AITT certificate of successful completion, delegates must answer 80% of the questions correctly.

Facilities and Equipment Required

Plant Moving

Aim

This essential course has been created to meet the specific needs and challenges within the tool hire industry to train employees in the safe and effective moving of tool hire small plant around the yard.

Course Duration

Objectives

Delegates will understand how to safely and efficiently move plant around the yard.

Elements Covered

Legislation and guidance including:

Facilities and Equipment Required

Get in Touch

If you’d like further information on up-skilling your workforce, please contact us on 0121 380 4617 or by e-mail training@hae.org.uk.